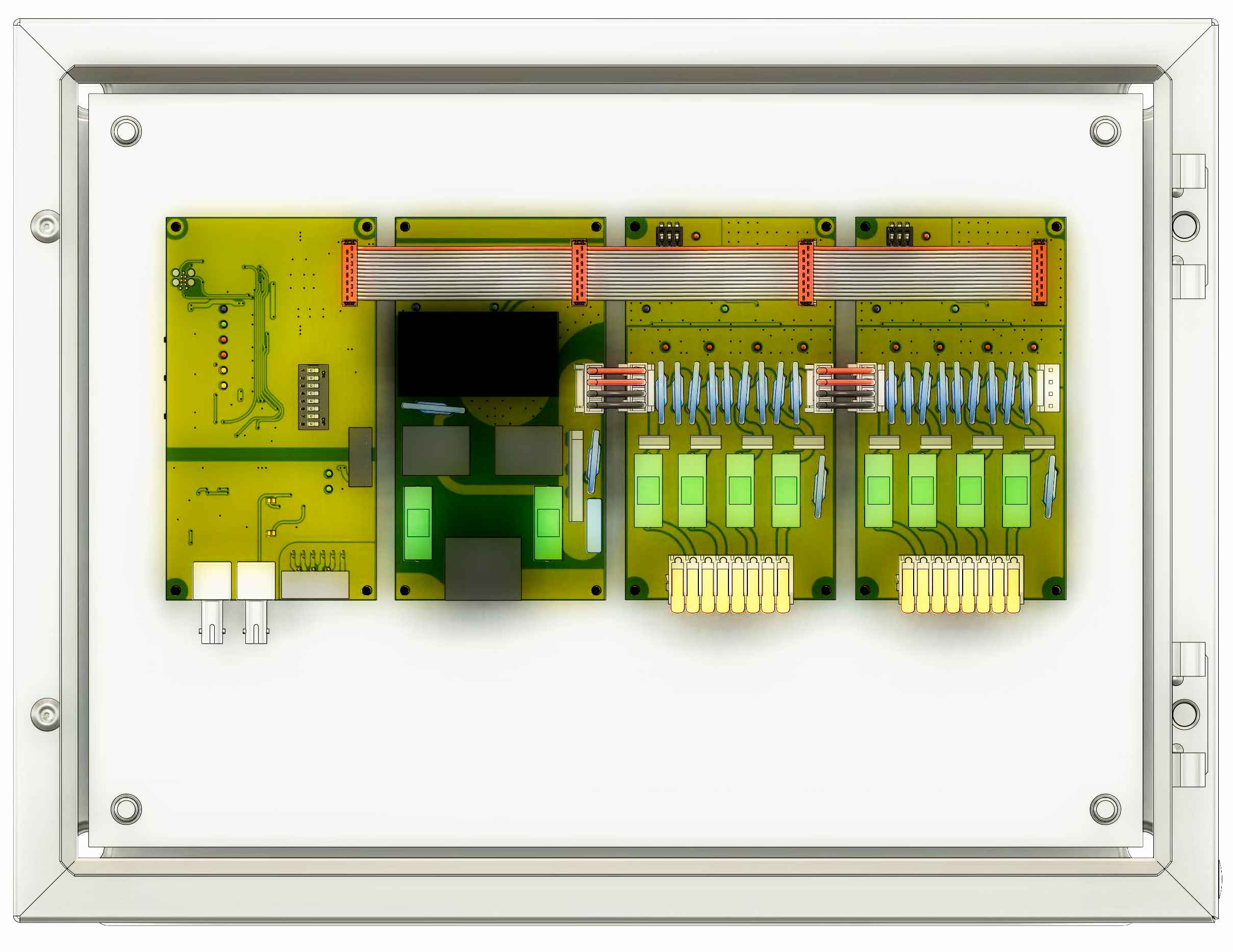

Libertas 3700 series modular relay and high current switching panels provide consistent ringing with accurate pulse timing.

Technical description

From left to right, each panel includes the following modules

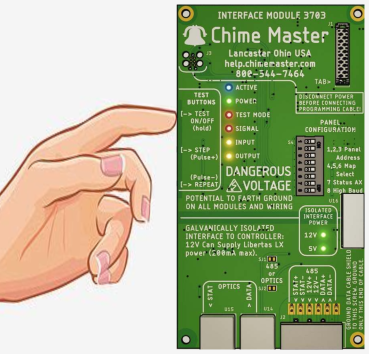

- Interface Module

- Power Supply Module

- Output Module(s)

- DC Striker T4 - four DC striker outputs

- Combination Output - one DC striker and three motor control dry contact relays

- Relay Module M4 - four dry contact relays, typically used for motor control

Module Connections and Warnings

The modules are tied together using a ribbon cable that carries low current power, control voltages and logic signals. Additionally high voltage DC jumpers feed 200VDC from the Power Supply Module to the DC striker output modules.

CAUTION - HIGH VOLTAGE

There are no user or field serviceable parts on the modules. Send suspect or faulty modules to Chime Master for repair or replacement.

The low current ribbon cable at the top of the modules carries 12VDC and lower local potentials for logic signaling, but when a DC Striker module is part of the panel, the ribbon cable will have LETHAL VOLTAGES from the ribbon cable to EARTH GROUND when the Blue ACTIVE lights are on.

Do not attempt to troubleshoot or reprogram logic when DC Strikers or Combination Modules are connected to the power supply DC HI VOLTS header J2. The logic low current ground is not isolated and is referenced to -200 VDC.

SAFE CONFIGURATION

The interface module features both a galvanically isolated, twisted pair wired interface to the control panel and an optional optical interface. Interface Module connectors located at the lower portion are safe.

When the modules are secured to the relay panel, and cables are installed, high voltage present on the bottom of the modules is not touchable. The test button housings are grounded to the electric panel, which is bonded to Equipment Earth ground attached to the power supply module.

Interface Configuration Switch

- Panel Address

- Non-musical bell controls: 1, 2, 3 - OFF

- First panel for Carillons: 2, 3 - OFF; 1 - ON

- Second panel for Carillons: 1, 3 - OFF, 2 - ON

- Third panel for Carillons: 2, 3 - OFF; 3 - ON

- Map Select

- Non-musical bell controls: 5, 6 - OFF; 4 ON

- Chimes with missing semitones: 4, 6 - OFF; 5 ON

- Carillons: 4, 5 - OFF; 6 ON

- Custom: 4, 5 - ON; 6 - OFF (sticker on Interface Module has an Fnnnn number)

- AX Mode: 7 - not implemented yet

- High Baud

- Non-musical bell controls: 8 - OFF

- Chime and Carillons: 8 - ON

Module Address Switch

Typical chime and carillon Striker Modules are numbered left to right as 1 through 5. Set module 4 as 3+1, module 5 as 3+2. Only large carillons will have a module 0 (all off) to the left of 1.

For non-musical controls there will typically be up to two DC Striker modules and up to two Relay modules. The Striker modules are numbered 0 (all off) and 1, and the relay modules are numbered 2 and 3.

Combination Modules do not have address switches.

Installation

Primary power from the local disconnect is connected to the Power Supply Module at L1 and L2. Earth safety is tied to the third terminal with the ground symbol (bonded to the chassis).

Strip input and output wires to 3/8 inch (10mm) for lever action terminals. Take care to insert all strands of wire into the terminal and that they do not contact each other outside the terminal.

AX Systems

The 485 input connector is pinned out one to one the same as the AX tower connector. When multiple panels are used, parallel the data cable to all panels.

Four wires (two twisted pairs) are enough unless AX STATUS mode is used (not implemented at the time of this writing).

- STAT+ (status from the panel to the controller)

- STAT-

- 12V+ (used to power the isolated inteface in the controller)

- 12V-

- DATA+ (control data from the controller)

- DATA-

LX Systems

Sufficient power is available from the 12V terminals of the interface to operate the LX control panel. If the data cable length causes the supply voltage to drop so that the LX control panel does not operate, try the following remedies.

- Use additional spare wires in the data cable to carry more current.

- Plug a booster power suppply into the 12VDC input of the control panel.

- STAT+ (not used)

- STAT- (not used)

- 12V+ (connect to P+ terminal 4 on LX controller)

- 12V- (connect to P- terminal 5 on LX controller)

- DATA+ (connect to T+ terminal 1 on LX controller)

- DATA- (connect to T- terminal 2 on LX controller)

Troubleshooting

Lights in normal operation

Interface module

- ACTIVE: indicates the high voltage relays are enabled. Indicated from logic before drive transistor.

- Active only on when outputs are active. Resets at end of concert.

- POWER: 12VDC Power supply from Power Supply Module is on and 5V regulator is OK.

- Should be as bright as power light on Power module.

- TEST MODE: indicates self test is active. Inputs are ignored.

- SIGNAL: blinks with input data.

- Should never be constantly lit except dim glow in Bit Map mode.

- Blinks brighter when receiving low Baud signal.

- INPUT: indicates that input data addressed to this panel, or

- Steady Blink if configuration switch error.

- Will not blink if incoming activation data is for this panel, but no module has been installed for it.

- OUTPUT: indicates that this panel is sending status back to the controller.

- Blinks brighter when set for low Baud.

- 12V: DC-DC isolation converter is working - 12V available on 485 interface terminal

- Should be as bright as power light on Power module.

- 5V: interface regulator is working (may be damaged by surges induced to data cable)

- Should be as bright as power light on Power module.

Power module

- Power - 12VDC Power supply is working and AC input is within 100-240VAC

- Active - indicates the high voltage relays are enabled. Indicates Interface Module drive transistor is OK.

Output modules

- Ready - indicates that interface module has enabled the outputs (not in sleep or reset mode).

- Active - indicates the high voltage relays are enabled. Indicates signal over cable is OK.

- ERR - indicates improper signal received for module (if input not blinking on Interface module).

Error lights

Configuration error

Configuration errors are indicated by blinking Input light on the interface board. If no error lights are lit on output modules then the problem is an invalid setting of the Panel Configuration switch on the interface board. If an error light is lit on an output module, its address switch is incorrectly set for that type of panel.

Correctly configured modules will result in a self test that activates outputs from left to right (in Up sequencing mode).

- Two modules error lights do not come on (other modules do)

- Modules at the same address must be the same module type - the modules with Err lights off are the problem

Operational error

If error lights occur on output modules, the following operational errors may be indicated:

- All module's error light comes on and stays on.

- If Bit Map mode is selected, a constant input data stream is needed. Check connections between the panel and controller. The interface module's Signal light sould be indicating presence of the input signal. Perhaps the controller has not been configured for Bit Map mode.

- One module error light comes on. The error resets when the Active state comes on next time.

- This indicates that the output pulse exceeded the modules maximum pulse time. Reduce the pulse time on the controller (AX or Bit Map modes).

Test buttons

Self test will time out to normal operation in three minutes (from last output test) unless it is left in the repeat or scan modes. Those modes will operate continuously until canceled.

- Quick Tests

- Long Press Test- enters test mode from normal mode - exits test mode

- Double Click Test - test reset to output 1 up direction

- doesn't fire output

- discards all output timing edits

- Click Test - cancel repeat/scan modes, reverse direction

- Click Step - cancel repeat/scan, go to next available output and fire

- Click Repeat - cancel repeat/scan, fire current output again

- Leave panel in test mode for burn in or bell adjusting (CAUTION! No Time Out)

- Double Click Step - fire next, continue scan all outputs until cancel w/single click

- Double Click Repeat - continue to fire current output - repeat until cancel w/single click

Adjust output pulse time

Does not affect motor enable outputs to intelliSwing panels, but will affect Relay modules if used to trigger striker outputs.

Initial pulse times available (milliseconds - Input LED blinks):

- 75 - one blink - only for very small bells in chimes and carillons for faster repeat

- 100 - two blinks

- 150 - three blinks

- 200 - four blinks - Default

- 250 - five blinks

- 300 - six blinks

- 500 - seven blinks - only for Deagan strikers

- 600 - eight blinks - only for stubborn Deagan strikers

Click the Step button to get to desired bell output, then long press Step or Repeat until Input LED indicates new pulse width.

- Long Press Step - (up) lengthen output pulse

- Long Press Repeat - (down) shorten pulse

- Click Repeat - re-test using new pulse

- Double click Test - revert to last saved pulse times (losing any recent changes)

- Long Press Test - saves newly selected timing for all bells before exiting self test

- During save, Input LED blinks four times

If you want to reset to default pulse times

- Change the module configuration (unplug a module temporarily) and cycle power

DC Striker Module

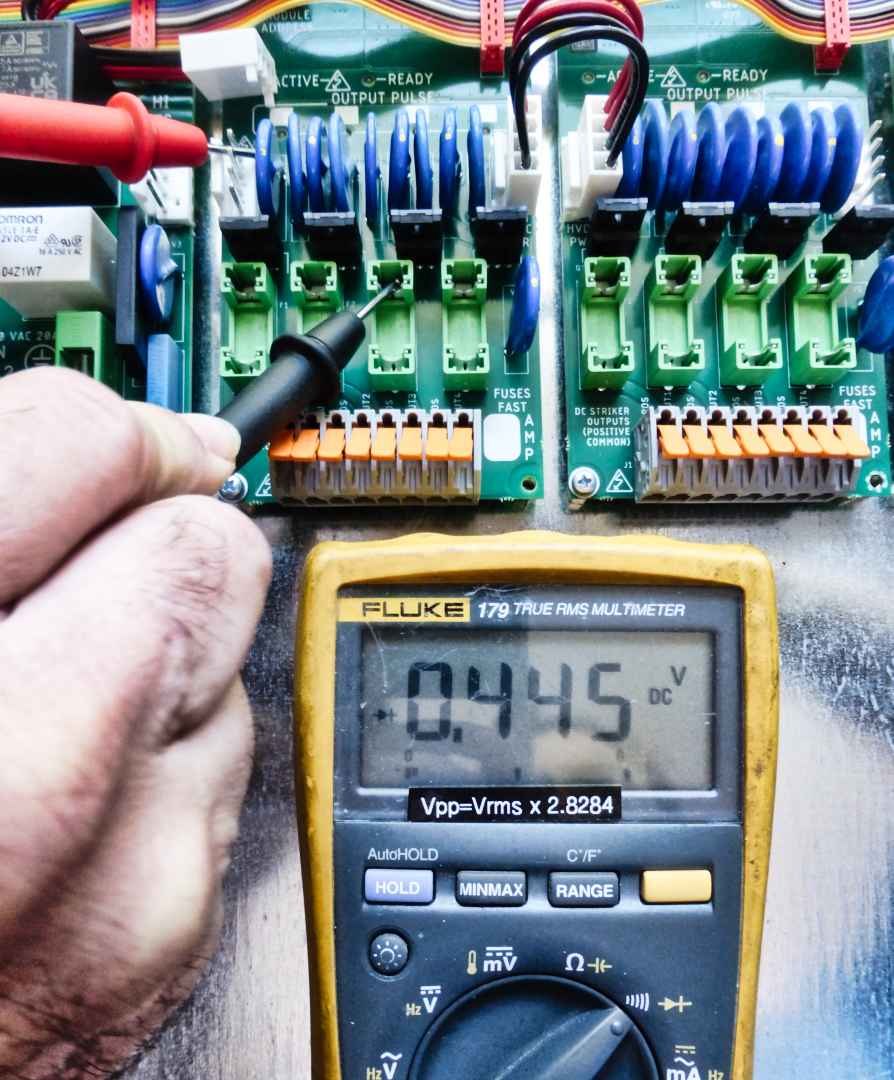

You can use a digital multimeter to check the IGBT output drivers of the DC Striker Module.

- Make sure the panel is powered off (circuit breaker or local disconnect)

- Unplug the power cable from the Power Supply Module that feeds high voltage to the DC Striker Modules

- Remove the output fuses from the module

- Set the multimeter to Diode Junction test mode

- Hold the red meter probe to the top power pin

- Check the top contact of each fuse holder on the module

- The voltage drop should be around 0.5 Volts - shorted outputs will be near 0 Volts (and fuse will be blown - do not replace)

- Return the module to Chime Master for replacement/rework if any measurement is less than 0.35 Volts

Repairs

Do not unplug cables or make wiring changes while module power lights are on. Turn off circuit breakers or disconnects first.

When replacing a module with a configuration or address switch. Make sure that the switch on the replacement module matches that of the original module before powering the panel.