IntelliSwing rotary sensor setup: Difference between revisions

(P-regulator ideals) |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 209: | Line 209: | ||

*Polarity (initial direction +/- effectively reverses motor leads U and V) | *Polarity (initial direction +/- effectively reverses motor leads U and V) | ||

*Brake Angle (angle where brake switches from Power Brake 1 to 2) | *Brake Angle (angle where brake switches from Power Brake 1 to 2) | ||

*PowerStaSwi (power reduction | *PowerStaSwi (power reduction for over-powered motors) | ||

** 9 - No soft start - full power - mechanical shocks may damage motor mounts | |||

** 8 - (default) Soft start - full power | |||

** 1 to 7 - Soft start - reduced power | |||

*Power Brake 1 (first brake current limit) | *Power Brake 1 (first brake current limit) | ||

*Power Brake 2 (second brake current limit) | *Power Brake 2 (second brake current limit) | ||

*MaxAmpl (maximum angle before error and shutdown) | *MaxAmpl (maximum angle before error and shutdown) | ||

*P-Regulator - Proportional regulation factor (amount added/subtracted to pulse to compensate for under/overshoot) | *P-Regulator - Proportional regulation factor (amount added/subtracted to pulse to compensate for under/overshoot) | ||

** Ideal values are close to 50 for a well matched motor. If they are much lower, try reducing the PowerStaSwi setting. | |||

*I-Regulator - Ideal pulse - (Will be 0 after automatic calculations. Manually set this to zero after manual experimentation, but make a record of what was set) | *I-Regulator - Ideal pulse - (Will be 0 after automatic calculations. Manually set this to zero after manual experimentation, but make a record of what was set) | ||

** read calculated I from the bottom center of the status screen | ** read calculated I from the bottom center of the status screen | ||

Latest revision as of 17:09, 2 December 2024

The Chime Master intelliSwing™ Precision bell ringing system consists of a rotary or linear swinging motor with an optical rotation encoder and a wall-mounted motor power control unit. This mathematically brilliant motor controller experiments and quickly learns the unique physical properties of your bell then carefully manages the energy required for perfect ringing and never overshoots the desired swinging angle.

Three phase and single phase bi-directional motors are available with this system. Very large bells are supported with the use of dual motors.

Wiring

Motors are numbered from largest to smallest when multiple bells are connected.

Sensor feedback

The sensor is mounted on the side of rotary motors opposite the drive spindle. In the case of MagForce linear motors, the sensor is provided in a separate box and is linked to the yoke spindle of the bell.

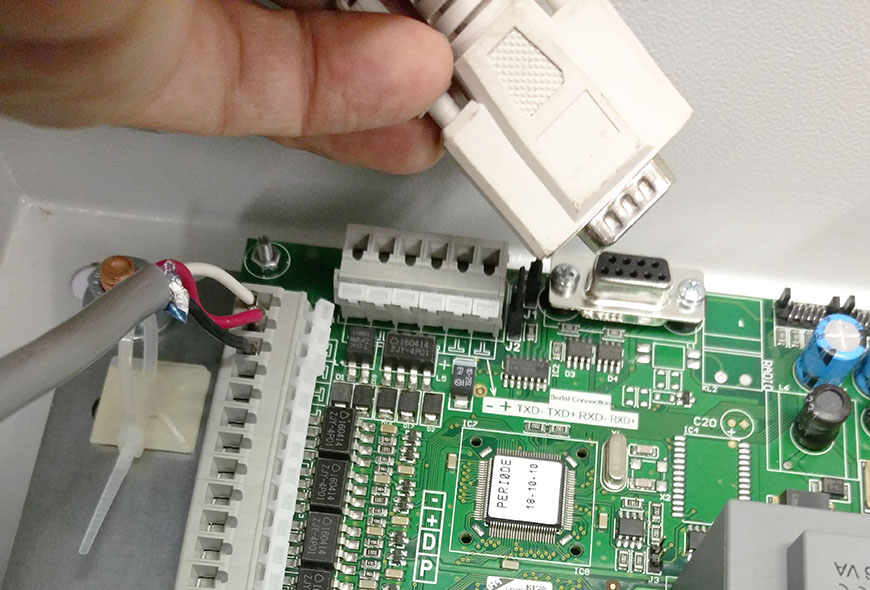

Four conductor cable connects the sensor board to the motor control panel. The four terminals are labeled:

- - (negative 12V)

- + (positive 12V)

- D (direction)

- P (pulses)

If the panel drives up to four motors, the bell number is on the terminal label too.

MagForce sensors

These rotary sensors are very fragile. Take care when mounting the sensor to the bell frame.

An active logic junction box is located near the sensor box providing connections to the cable that provides low voltage feedback to the controller.

Three phase power to motor

The motor output terminals are labeled, W, U and V.

- U - switched between L2 and L1 to reverse direction

- V - switched between L1 and L2 to reverse direction

- W - always fed from L3 power

Three phase rotary motor terminals will have corresponding W, U and V terminals. Use the supplied shorting plates to wire the motor in the DELTA configuration.

The six power leads from linear motors are made up in a junction box next to the motor to the three leads feeding from the three output terminals.

- U - connect to linear motor leads 1 and 6

- V - connect to linear motor leads 2 and 3

- W - connect to linear motor leads 4 and 5

Single phase power to motor

Modular triac board

Triac relay board POWER INPUT wiring:

- L1 - from L1 output of the power contactor

- L2 - NO Connection!

- L3 - from L2 output of the power contactor

The motor output terminals are labeled, U,V and W (top to bottom).

- U - switched between L1 and OFF for forward rotation

- V - switched between OFF and L1 to reverse direction

- W - always fed from L2 power (through L3 terminal of triac board)

Motor with internal capacitor

If the capacitor is on the motor it will be between terminals 1 and 2.

- U - connect to motor terminal 1

- V - connect to motor terminal 2

- W - must be connected to motor terminal 3

Motor without built-in capacitor

We mount capacitors in the motor control panel for MagForce linear motors. Connect the capacitor(s) to terminals U and V (not polarized). The six power leads from the motor are made up in a junction box next to the motor to the three leads feeding from the three output terminals.

- U - connect to linear motor leads 1 and 6 (capacitor for single phase)

- V - connect to linear motor leads 2 and 3 (capacitor for single phase)

- W - connect to linear motor leads 4 and 5 (IMPORTANT! NO capacitor lead)

If overload trips during setup, recheck the output wiring. The L1 lead from the contactor must be routed through all three overload phases (sepentine fasion) to prevent missing phase detection.

Programming the controller

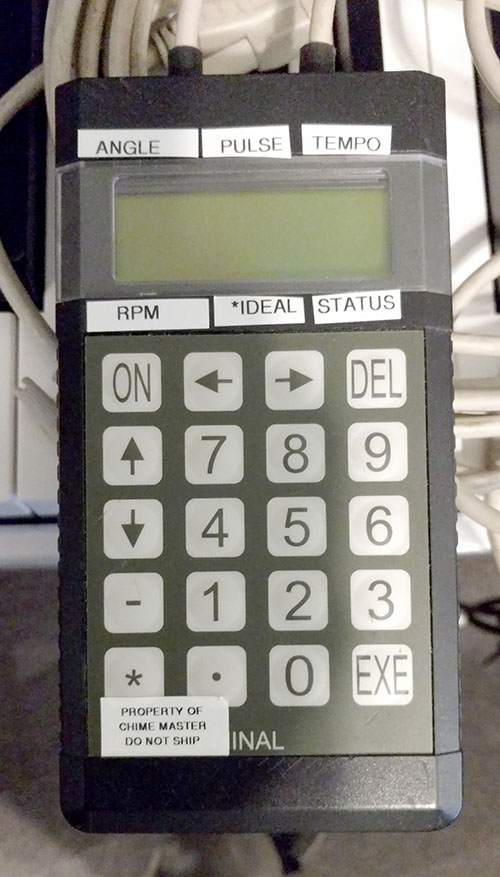

The intelliSwing motor control system must be programmed with the bell at the time of installation. A special hand-held terminal is required for this setup and is available on loan from Chime Master with a deposit.

Precision angle sensing

Either a slotted code wheel with sensors are mounted to the motor or a rotary sensor assembly is coupled to the swinging bell axle for this system to accurately measure the swinging angle and direction.

The label on the motor control computer PCB should read 'SENSOR.' For motors without a code wheel and sensor, a proximity switch is used for motion feedback. In that case, verify that the CPU chip on the intelliSwing Precision motion controller has a label that reads 'PERIOD' and use the MagForce PERIOD programming procedure.

For each bell we need to calculate the value for Transmission. Take the diameter in inches of the wheel (on the rim where the chain runs) multiplied by 6.28 (π divided by the chain pitch, generally 1/2 inch) and divide the result by the number of teeth on the cog.

For example a 60 inch wheel with a 28 tooth cog will have a transmission ratio value of 13.5. The system will accept values from 5.0 to 45.0.

Transmission = (diameter x (π / chain pitch)) / cog teeth (60 x (3.14/0.5)) / 28 = 13.5

For belt drives, simply divide the wheel diameter by the motor cog diameter.

Precision Sensor on MagForce motors

For linear MagForce motors with a Precision Sensor rotary sensor on the bell's swinging axle, set Transmission to 22.8.

Using the terminal

The terminal is simply a display and keypad for the control board during installation and setup. All parameters are stored on the control board, and the terminal remembers nothing.

Connect the programming terminal and turn on panel power. The right cursor button will take you through the settings for each bell in the system. From the status window, shown below, you can cursor left to select another bell. To change settings you can increment/decrement using the up and down arrow buttons, or input the value with the numeric buttons and save it with the EXE button.

Display

After changing parameters, try always to return to the status screen when running the bell. The two line programming status screen should look like this (first and fourth lines are our labels):

Swing Angle Motor Pulse Time Tempo

60.4 17 #46.8

804 *16 Start

Motor RPM (*Sensor) Ideal Pulse Status

When the bell is swinging, the display will indicate the current Swing Angle to the nearest tenth of a degree, the Motor Pulse time in milliseconds, the Tempo in beats per minute, the motor RPM (for rotary) and "*" will blink when feedback from the sensor occurs. The Ideal Pulse is the time in milliseconds that will maintain the desired swinging angle. Status will be Start, Stop, Restart, StartP, Calc-P or Calc-Imp, indicating the swinging/calculation mode.

Keypad

- Use the left and right cursor buttons to move through the setting screens.

- Use the numeric buttons to enter parameter values, then press EXE to save them

- Use up and down cursor buttons to make small changes to the displayed value

- Cursor up will change the Polarity parameter to Negative

- Cursor down will change the Polarity parameter to Positive

- The ON button starts and stops the motor, and clears errors

First!

Check operation of the sensor. Move the bell by hand and you should hear the phase reversing relay click when the bell reverses direction when the D light on the relay board goes on and off.

Set Swing Angle and other initial parameters

- Set Transmission to the supplied value or the ratio you calculated above for rotary motors. Set Transmission to 22.8 for linear motors.

- Set %Start to 50 if setting up a rotary motor at an angle of 45 degrees or more with an easy to swing bell. After reset, percent of start is 95. You can enter values up to 100. The effects of this parameter depends on the version of software in the controller, so you may need to experiment to get the bell started most efficiently.

- Set %Brake to zero while in the setup mode to prevent overheating while testing.

- Set Angle to a modest value like 25.0 degrees to determine the bell swings safely before going higher.

- Set MaxAmpli to a large value like 90 to 120 (unless there are obstacles the bell might collide with) it will default to ten degrees higher than Angle before auto calculations then 5 degrees higher when testing is complete. A higher value will prevent error shutdowns for exceeding the maximum angle during experimentation (error status = MaxAmpli).

- P-regulator and I-regulator both default to 50 for fully automatic calculations. You will also get fully automatic calculations for both values if you choose lower, but equal values. First I will be calculated, then after you stop the bell, you will be prompted to restart it for calculation of P. At the end of fully automatic calculations, you will find that the I parameter is zero. You can read the actual value for I from the middle of the lower line of the programmer.

If P is modified manually and I is left at 50, only the I value will be calculated. You will not be prompted to restart the motor after the I has been calculated.

If both parameters are modified, the system will still hunt for its ideal pulse (shown on the display at middle bottom on the main page). In this manual setup mode, stop the bell when you have it swinging properly and then manually set I to zero to save that value so the system doesn't continue to 'hunt' for the best value every time the bell rings.

If the bell is easy to swing a quicker semi-automatic calculation will result with both P-regulator and I-regulator both set to 25. Try the default of 50 first, then change to 25 (with a strong motor) if the CalcImp mode seems to ‘hunt' for a long time. If the motor is suspected to be weak for the bell, increase P.

The automatic calculations should be finished within ten minutes. If it is taking longer and you are happy with the way the bell is ringing, you can terminate the calculations using the current settings. To do this, keep the bell swinging and set I-regulator to zero. The display will change to Swing and you can stop the bell. Make sure it starts correctly with the saved values after coming to a complete stop.

Automatic calculation

The bell needs to swing two times (full automatic setting) so the controller can experiment with the required pulses. These parameters will only be saved after the bell has been rung twice.

The first time it will say Start then Calc-Imp then Swing. After you stop the motor the status display will read Restart.

The second time will say Start then Calc-P then Swing. The calculated parameters are not saved until the status display reads Swing, and then after you stop the motor the status display reads Stop. At this point, the calculated parameters have been saved in non-volatile memory, so power can be safely turned off.

First Swing Experiment

Calculating the ideal impulse

Press ON to start the first experiment. Status on the lower right of the display will read StartP until the system has fired the number of impulses you specified in StaImp. Next it will read Start as it approaches the desired angle. When it begins to search for the ideal pulse, it will read CalcImp.

- If the bell isn't swinging high enough to ring, but the controller stops sending power impulses to the motor during CalcImp, then increase the Angle parameter. This can be done while the bell is swinging as re-calculation will be performed as you make these changes.

- If the bell seems to be fighting itself to get started, change Polarity to - (negative). You can reverse the U and V motor wires instead of changing polarity in the program if you want the bell to initially swing the other direction.

- ErrAmp errors occur if the bell swings higher than the MaxAmpli parameter. Raise that value, or reduce power in the %Start (first) and PowerStaSwi (second if you still have too much power) parameters.

- If you get ErrBlo (blocked bell), double check the sensor hookup and operation. Double check all motor current connections for integrity (the most common point of failure).

- When Swing appears on the display, the system has calculated the ideal impulse (middle value on the lower line on the status screen) to maintain the requested angle. If you would like the bell to swing higher or lower, try other values for Angle and MaxAmpli. It will recalculate the ideal impulse based on changes you make at this time.

- When you like the angle and the display again says Swing you can press ON to stop the bell swinging. Wait for the bell to come to a full stop.

- The terminal display will indicate Restart to indicate that automatic setup is not yet complete.

Second Swing Experiment

Calculate the over/under Proportional correction factor

The system will not require a second swing if you set P-regulator to a value not equal to I-regulator. It will use your parameters and expect you to verify that your values will work properly.

Press ON to start the second experiment. The terminal display will say CalculP while it is determining the setting for the P-regulator. This is the amount that will be subtracted from the ideal motor pulse when the bell swings too high. It is also added to the ideal motor pulse if the motor swings too low.

When Swing appears on the display, the calculation is complete and you may press ON to stop the bell. Wait for the bell to come to a full stop.

In some cases, the display may continue to say Restart instead of Stop after the second calculation because the motor may not be ideally sized for the bell, so values for P and I could not be found in the normal range. If this occurs, tweak the PowerStaSwi (and maybe P/I-regulator if that doesn't help, see above) parameter and press ON again until you see Swing. You have not successfully finished the setup and the parameters are not permanently saved until you reach status=Swing and then status=Stop after stopping the bell.

Interpreting the results

Calculated values of P-regulator will provide you with information regarding the ease that system has ringing the bell. Low values of P-regulator (< 25) indicate that the motor easily swings the bell. You can reduce PowerStaSwi which is the soft start current limit parameter to pulse the motor more gently.

Testing performance and re-calucuating after making adjustments

Further experiments (first and second swing) must be re-run if you adjust Angle, PowerStaSwi, Pos-Impuls or Transmission after calculations are complete.

Saving the settings

IMPORTANT - The ideal impulse has not been written to permanent memory unless I-regulator is zero. It will automatically go to zero if the system calculated the value. If you entered your own value for I then you will also have to set I-regulator to zero yourself to save it in memory (manual setup mode), then swing the bell again to make sure it works.

Adjustments to %Start, %Brake, PowerBrake1 and PowerBrake2 can be made at this time without having to recalculate ideal pulses. You can test them to be sure the motor overloads don’t pop when this happens.

Do not use braking with retrograde (counterbalanced) clappers. Bell damage from a severe impact may occur if the clapper gets out of phase with the bell and they collide from opposite directions.

Adjust Assym as needed so that the clapper rings evenly on both sides of the bell. In a peal, you should have at least 2 to 3 bpm difference in the Tempo between individual bells. If you cannot accomplish this by modifying swinging angles, then you can add mass to the top of the headstock to slow a bell down.

Stationary Overload Test

After everything else is completed, you can adjust the motor overload (if installed on 1HP and larger motors) current setting to trip within 40 seconds of a locked rotor condition. Click the left arrow (5 clicks) from the Status screen until you get to the Test-PKZ page. Press the ON button to turn on all phases in such a fashion that the motor does not run (simulation of a locked rotor). Then adjust the overload so that it trips before the on-screen timer reaches 40 seconds.

Note that on single phase systems, the L2 supply leg (to L3 on the TRIAC driver board) must be routed through all three circuits of the overload interrupter. Overloads are designed to detect missing phases this way and will trip quickly if one is detected to be missing. This should have been done at the factory unless a three phase panel was ordered. To rewire the overload for single phase,

- Connect the L2 supply to L1 on the overload,

- then a jumper wire from T1 to the L2 terminal,

- then jumper from T2 to L3.

- Finally connect the overload's T3 terminal to L3 on the TRIAC driver board.

- The TRIAC board's L2 input terminal is left disconnected.

L1 can bypass the overload on the way to the TRIAC board.

Final Settings

Make a record of the following settings for future reference when setup is complete:

- Bell Number (1 is the largest bell)

- Tempo (speed of ringing in beats per minute)

- read this from the top right of the status screen while the bell is in the Swing mode

- Swing Angle (intended angle)

- Transmission (rotary cog to wheel ratio)

- 22.8 for linear MagForce motors

- %Start (starting pulse maximum length before sensor is detected)

- %Brake (portion of swing angle for braking action when turning off the bell)

- Polarity (initial direction +/- effectively reverses motor leads U and V)

- Brake Angle (angle where brake switches from Power Brake 1 to 2)

- PowerStaSwi (power reduction for over-powered motors)

- 9 - No soft start - full power - mechanical shocks may damage motor mounts

- 8 - (default) Soft start - full power

- 1 to 7 - Soft start - reduced power

- Power Brake 1 (first brake current limit)

- Power Brake 2 (second brake current limit)

- MaxAmpl (maximum angle before error and shutdown)

- P-Regulator - Proportional regulation factor (amount added/subtracted to pulse to compensate for under/overshoot)

- Ideal values are close to 50 for a well matched motor. If they are much lower, try reducing the PowerStaSwi setting.

- I-Regulator - Ideal pulse - (Will be 0 after automatic calculations. Manually set this to zero after manual experimentation, but make a record of what was set)

- read calculated I from the bottom center of the status screen

- Pos-Impulse (Position of the motor impulse in the sweep of the bell; 0=home 100=turnaround)

- must be 0 for linear MagForce motors

- Assymmetric (Proportion of motor pulse for forward/backward balance; 50 = equal, 100 or 0 = unidirectional drive)

After setup complete

Disconnect the programming terminal. The front panel switches and the Chime Master relays will not activate the motors while the programming terminal is connected.

Troubleshooting

Clear all programs

To restore the panel to the factory default settings (all bells),

- Power on the panel with the programmer plugged in

- Click the left button until you reach the Language select screen

- Press the DEL button. The display will say STOP.

Errors

When the system is displaying an error, it will not show sensor feedback when you move the bell by hand. It will not activate the braking action if the bell is swinging.

- To clear the error, Press the ON button so that the display reads STOP

ErrBlo

If the screen shows 'ErrBlo' on the lower right of the screen, the system thinks the bell is not moving as expected. This can be caused by:

- Loose connections to the motor or the sensor

- Motor is mis-wired

- Sensor is mis-wired

- Motor is undersized or mounted in a way that prevents it from generating enough torque.

ErrAmp

If the screen shows 'ErrAmp' on the lower right of the screen, the system detected that the bell went higher than the selected MaxAmpli setting. Every time you modify the Swinging Angle setting, the system will add five degrees to that setting for MaxAmpli. To avoid errors while setting up the system, set MaxAmpli to 90 degrees, or a safe angle in case of overshoot.

Sensor Test

While the screen shows 'STOP' you can move the bell by hand. The D light on the motor output board should blink to indicate the direction the bell is swinging. The top left number on the terminal display should show the angle the system thinks the bell is swinging. If you do not get these indications, check the sensor wiring.