Bell Ringing Components: Difference between revisions

(spec - spec link) |

|||

| Line 45: | Line 45: | ||

Movement of bells or strikers is generally accomplished by electro-mechanical means. Motors and electromagnets require large amounts of electric current to put these heavy components into motion. | Movement of bells or strikers is generally accomplished by electro-mechanical means. Motors and electromagnets require large amounts of electric current to put these heavy components into motion. | ||

Alternatively, compressed air can be used as a pneumatic source of power while low current electro-mechanical valves pulse the flow of air into the actuators. Pneumatic strikers have been fitted, especially to tubular tower bell chimes. [ | Alternatively, compressed air can be used as a pneumatic source of power while low current electro-mechanical valves pulse the flow of air into the actuators. Pneumatic strikers have been fitted, especially to tubular tower bell chimes. [[Pneumatic_actuation|Pneumatic 'fingers']] have been fitted to traditional carillon keyboards for automatic play. | ||

=== Electronics === | === Electronics === | ||

Revision as of 18:00, 31 December 2020

Mechanical Components

Bell

The bell itself is the resonant portion of the system that provides a musical tone when struck. The General Campanology page provides a list of additional pages for further study into the physics of bells.

Suspension

In order to ring, the bell must be hung in such a way that it can freely resonate. Traditional bells are generally suspended from the top. This can be accomplished by simply providing holes for attaching bolts, or an optional crown top is provided for attachment.

Beams of wood or metal have been used for suspending bells. Wood has the advantage of being non-resonant. Double C-channel steel is often used to mount bells by placing the center bolts of the bell through the slot between channels. Tubular steel is the most unfavorable because of its resonant qualities that are detrimental to the sound of bells. Isolation materials must be used when multiple bells are suspended from the same beam to inhibit sympathetic vibrations.

Swinging Bell

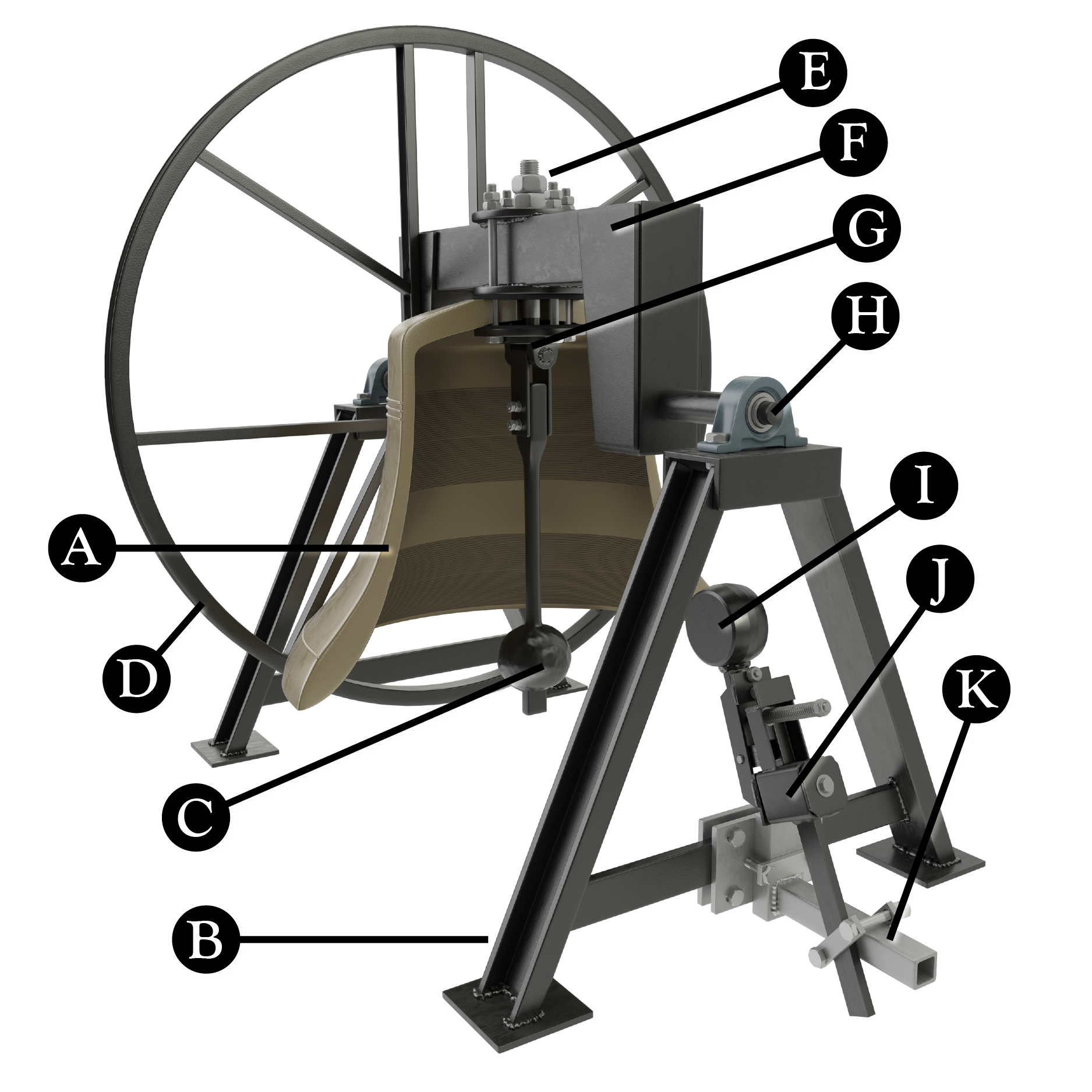

A swinging bell (A) is shown in the diagram with a wheel and electric hammer.

A-Stand and Headstock

A swinging bell is typically gimbal mounted to a headstock to allow free swinging. In the illustration the headstock (F) has welded on axles inserted into a pillow block style ball-bearing (H) that is attached to the top of the A-stand (B) which is designed to support the weight and swinging forces of the bell and transfer them to the tower structure (not shown).

Headpiece and Clapper

The bell is suspended from the Headstock with a headpiece (G) that distributes the weight of the bell evenly between the suspension bolts (E). The headpiece for a swinging bell has a pivot (generally a clevis type) from which the free swinging clapper (C) is mounted. For free-swinging bells, the clapper is usually mounted to a hinge near the top center of the bell, aligned with the swinging axis of the bell so that it can strike the bell both fore and aft. Gravity and the motion of the clapper pivot relative to the bell gimbal axis cause the free clapper to strike the bell in its distinctive ding-dong fashion.

Wheel

Traditionally, pulling a rope attached to the wheel (D) rings a swinging bell. The wheel is attached to the headstock (F). Ropes will only allow the bell to be pulled in one direction. Chain or belt driven motors with position feedback can be used to pull in both directions.

For a cleaner visual aesthetic and quieter mechanical performance, modern MagForce induction motors do away entirely with the need for a wheel. Only an aluminum plate is mounted to the headstock. The motor, attached to the A-stand induces currents into the plate without physical contact.

Tolling Hammer

The lively sound of one or more bells swinging evoke a celebratory atmosphere. This is used for calling people to church or celebrating special events.

When announcing times of prayer or mourning, a toll of the bell while it is stationary is more appropriate.

The diagram shows such a hammer (I) actuated by an electromagnet (J) that allows an electric bell control system to sound the hour, announce prayer times or count the age of the person being memorialized.

Stationary Bell

Striker

We use the term striker to describe an element with an arm and head that excites a percussive instrument to resonate when they contact one another with a blow of some force. Actuation of the striker, regulation of the force and mass of the head for various purposes are described below.

Internal clapper

We refer to any striker that is mounted inside the bell as a clapper. For stationary bells, the clapper is typically supported close to one ideal strike point and an externally applied force moves the head toward the bell for a single strike.

Hand held mallet

Used to play orchestral bells, gongs and metallophones, these mallets consist of sticks with heads of relatively soft materials.

Electrical Components

Actuators

Movement of bells or strikers is generally accomplished by electro-mechanical means. Motors and electromagnets require large amounts of electric current to put these heavy components into motion.

Alternatively, compressed air can be used as a pneumatic source of power while low current electro-mechanical valves pulse the flow of air into the actuators. Pneumatic strikers have been fitted, especially to tubular tower bell chimes. Pneumatic 'fingers' have been fitted to traditional carillon keyboards for automatic play.

Electronics

Automation controller

Modern bell ringing equipment makes use of the latest electronic technology to control bell ringing schedules, ringing patterns and music as well as providing time synchronization and convenient remote control options.

Power switching

Advanced power switching panels ensure that high currents are applied to the ringing components only as long as it is needed. This keeps the tower safe from electric shock, prevents actuator overheating, and damage to the bell.

High voltage circuits should be switched through dry mechanical relay components because even the most advanced solid state circuits leak some currents. Solid state power switching is only acceptable when a dry master contactor enables the high voltage to the individual outputs only during ringing.